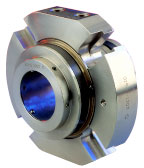

ZLR-1200 Series Double Mechanical Seals

ZLR-1200 Series Double Mechanical Seals

*Ideal for highly corrosive applications, all parts in contact with pumped fluid are made of corrosion resistant materials!

- Concentric Design – Places both rotary faces close to bearings to minimize deflection and vibration effects on seal.

- Cartridge Design – No measuring, self centering installation. Just slide over shaft, tighten gland bolts and set screws, remove centering clips, and the seal is ready to operate.

- Rotating Vanes – Ensures flush fluid circulates 360° for maximum cooling cleaning and lubrication of the seal faces. It also generates flow and pressure when a closed loop barrier fluid system is used.

- Double Balance – Allows the seal to be used as both a double seal (higher pressure barrier fluid or flush) and as a tandem seal (lower pressure barrier fluid) with the same hardware. Design also handles pressure reversals without opening.

- No Shaft Fretting – No moving parts on shaft, means no shaft damage, and no need for a sacrificial sleeve.

- Gland Insert – For High Alloy Corrosion Protection.

- Stationary Seal Design – Springs do not rotate, ensuring highest resistance against destructive vibration harmonics.

- Slotted Gland – Allows “universal” use in most rotating equipment.