It’s all About Reliability!

Product Profiles

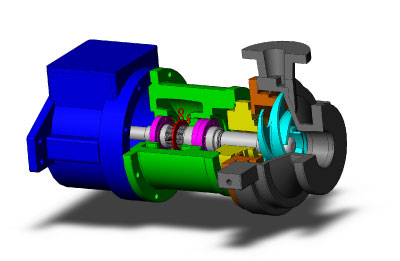

- Heavy duty “Next Generation” ANSI Process Pump, with sizes currently up to 8” x 10” x 17” in 316ss and EF-255 (duplex stainless steel) and power from 5HP-250Hp.PDF pamphlet

- For API-610 Process Pump applications, we have the same range of sizes and powers. The VIT Pump offers a highly competitive alternative for many API-610 process pump applications while meeting the API-610, 8th Edition specifications, plus offering several advanced features. Options are also available for specific applications for 8th Edition

- Both of the above lines can be sold as Upgrade/Retrofits to improve the life and performance of existing ANSI & API pumps. Our modular bearing frame/seal system is currently adaptable to nearly 200 different makes, models and sizes of ANSI pumps. We have also adapted the VIT Power Frame to ISO, DIN, JIS, Slurry Pumps, Self Priming Pumps, and others.

- Heavy duty Cartridge Mechanical Seals can be configured as a single seal, a double seal, a double concentric seal, or non-metallic double acid seal to fit most popular pump models.

- Non-metallic (carbon filled PTFE) Labyrinth Oil Seals for the replacement ANSI market and other popular pumps and rotating equipment.

There are currently over 200 patent claims covering the unique, proprietary features in the above product lines. Each of these lines continues to be further expanded in size range, complementary product lines, and materials on a regular expansion program as part of our strategic growth plan.

Our strategy is to assemble a wide range of MRO products, unique mechanical seals for the general ANSI/API pump population, and advanced ANSI & API power end upgrades to bring existing pumps up to a higher level of reliability